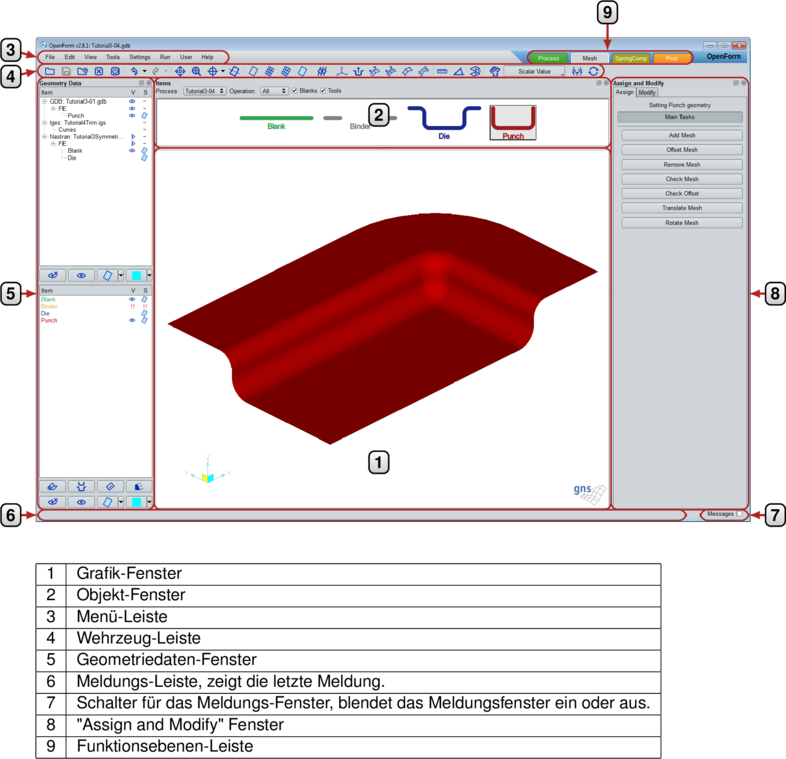

In a more advanced application, forming analyses and blank development are performed based on the draw-die 3D geometry created by AutoForm-DieDesigner.

For these analyses, the software allows you to modify the part and, when needed, automatically generate a blankholder surface and a schematic addendum. In the simplest application, AutoForm-StampingAdviser is used for early feasibility evaluations based on part geometry alone, without considering tool geometry. The software provides you with valuable feedback on key stamping quality issues, such as risks of splitting and excess thinning, potential for wrinkling and developed blank shape with its associated material costs. The software allows users to deactivate single geometrical features for shape change and activate them again if needed to evaluate alternative designs.ĪutoForm-StampingAdviser enables you to quickly and easily evaluate part and process feasibility as well as determine blank shape, material utilization and blank cost. Users can develop flanges on form tools not only during the design of the drawing operation but also for the secondary forming operations. As a result, the final part geometry can be efficiently realized within the required tolerances and with a minimum number of correction loops in tryout. With this version, they can visualize and compare the compensation strategies and then select the one that is best suited to their needs. By using AutoForm Forming R10, they can significantly speed up the process of die face generation.įurthermore, AutoForm Forming R10 allows users to easily evaluate different compensation strategies.

The software allows users to deactivate single geometrical features for shape change and activate them again if necessary in order to easily evaluate alternative designs. With this new version, users can develop flanges on form tools not only during the design of the drawing operation but also for the secondary forming operations. AutoForm Forming R10 offers new features to fully support die face generation.

0 kommentar(er)

0 kommentar(er)